-

question_answer1)

2000 cc. of air takes \[1{\scriptstyle{}^{1}/{}_{2}}\] minutes to pass through a standard Specimen of sand (5.08 cm high and 5.08 cm in dia.). The manometer indicates pressure as \[5\,\text{g/c}{{\text{m}}^{\text{2}}}\text{.}\] In this case the permeability number is:

A)

30 done

clear

B)

42 done

clear

C)

51 done

clear

D)

67 done

clear

View Solution play_arrow

-

question_answer2)

Match List-I (Moulding process) with List-II (Binding agent) and select the correct answer using the codes given below the lists:

| List-I | List-II |

| A. | Green sand | 1. | Silicate |

| B. | Core sand | 2. | Organic |

| C. | Shell moulding | 3. | Clay |

| D. | \[C{{O}_{2}}\]process | 4. | Plaster of Paris |

| | 5. | Plastic |

Codes:

A)

A\[\to \]3, B\[\to \]2, C\[\to \]5, D\[\to \]1 done

clear

B)

A\[\to \]3, B\[\to \]2, C\[\to \]4, D\[\to \]1 done

clear

C)

A\[\to \]2, B\[\to \]3, C\[\to \]5, D\[\to \]4 done

clear

D)

A\[\to \]2, B\[\to \]3, C\[\to \]4, D\[\to \]5 done

clear

View Solution play_arrow

-

question_answer3)

Which of the following are the processes for thermosetting materials?

| 1. Compression |

| 2. Transfer moulding |

| 3. Injection moulding |

| 4. Extrusion |

Select the correct answer using the codes given below:

A)

1 and 4 done

clear

B)

1 and 2 done

clear

C)

2 and 3 done

clear

D)

2, 3 and 4 done

clear

View Solution play_arrow

-

question_answer4)

Directional solidification can be achieved by providing:

A)

Chills and chaplets done

clear

B)

Chaplets and padding done

clear

C)

Chills and padding done

clear

D)

Chills, chaplets and padding done

clear

View Solution play_arrow

-

question_answer5)

Which of the following pattern-materials are used in Precision Casting?

| 1. Plaster of Paris |

| 2. Plastics |

| 3. Anodized aluminium alloy |

| 4. Frozen mercury |

| Select the correct answer using the codes given below: |

Codes:

A)

1 and 2 done

clear

B)

2 and 4 done

clear

C)

3 and 4 done

clear

D)

1 and 3 done

clear

View Solution play_arrow

-

question_answer6)

Match List-I (Casting process) with List-II (Applications) and select the correct answer using the codes given below the lists:

| List-I (Casting process) | List-II (Applications) |

| A. | Centrifugal casting | 1. | Carburettors |

| B. | Squeeze casting | 2. | Pipes |

| C. | Die casting | 3. | Wheels for automobiles |

| | 4. | gear housings |

Codes:

A)

A\[\to \]2, B\[\to \]3, C\[\to \]1 done

clear

B)

A\[\to \]4, B\[\to \]1, C\[\to \]3 done

clear

C)

A\[\to \]4, B\[\to \]3, C\[\to \]1 done

clear

View Solution play_arrow

-

question_answer7)

Match List-I (Material to be cast) with List-II (Shrinkage allowance in mm/m) and select the correct answer using the codes given below the lists:

| List-I (Material to be cast) | List-II (Shrinkage allowance in mm/m) |

| A. | Grey cast iron | 1. | \[7-10\] |

| B. | brass | 2. | 15 |

| C. | Steel | 3. | 20 |

| D. | Zinc | 4. | 24 |

Codes:

A)

A\[\to \]1, B\[\to \]2, C\[\to \]3, D\[\to \]4 done

clear

B)

A\[\to \]3, B\[\to \]4, C\[\to \]1, D\[\to \]2 done

clear

C)

A\[\to \]1, B\[\to \]4, C\[\to \]3, D\[\to \]2 done

clear

D)

A\[\to \]3, B\[\to \]2, C\[\to \]1, D\[\to \]4 done

clear

View Solution play_arrow

-

question_answer8)

Consider the following statements in respect of fabrication of plastic products:

| 1. Compression moulding is analogous to hot pressing of powdered metals. |

| 2. Jet moulding is a modification of compression moulding. |

| 3. Injection moulding is analogous to die casting of metals. |

| 4. Transfer moulding is similar to hydraulic extrusion. |

Which of these statements are correct?

A)

1 and 2 done

clear

B)

1 and 3 done

clear

C)

1, 2 and 4 done

clear

D)

2, 3 and 4 done

clear

View Solution play_arrow

-

question_answer9)

Which one of the following gating systems is best suited to obtain directional solidification?

A)

Top grating done

clear

B)

part-time grating done

clear

C)

Bottom grating done

clear

D)

stepped grating done

clear

View Solution play_arrow

-

question_answer10)

Which of the following are the characteristics of the injection moulding of plastics?

| It is the most economical method of mass producing |

| 1. a single item. |

| 2. In most cases finished products are obtained. |

| 3. There is lot of waste of thermoplastic since the |

| 4. Runners and sprues cannot be reused. |

Select the correct answer by using the following codes:

A)

1 and 2 done

clear

B)

2 and 3 done

clear

C)

1 and 3 done

clear

D)

1, 2 and 3 done

clear

View Solution play_arrow

-

question_answer11)

Which one of the following processes consists of central sprue to feel metal into the cavities through a number of radial gates?

A)

Centrifuging done

clear

B)

Semi-centrifugal casting done

clear

C)

True centrifugal casting done

clear

D)

Precision casting done

clear

View Solution play_arrow

-

question_answer12)

Match List-I (Name of the casting" process) with List-II (Process definition) and select the correct answer using the codes given below the lists:

| List-I (Name of the casting process) | List-II (Process definition) |

| A. | Die casting | 1. | This process involves use of a mould made of dried silica sand and phenolic resin mixture |

| B. | Electroslag casting | 2. | In this process, molten metal is forced by pressure into a metal mould |

| C. | Centrifugal casting | 3. | This process employs a consumable electrode |

| D. | Precision casting | 4. | This process involves rotating a mould while the metal solidifies |

| | 5. | This process produces very smooth, highly accurate castings from both alloys |

Codes:

A)

A\[\to \]5, B\[\to \]4, C\[\to \]1, D\[\to \]2 done

clear

B)

A\[\to \]2, B\[\to \]3, C\[\to \]4, D\[\to \]5 done

clear

C)

A\[\to \]5, B\[\to \]3, C\[\to \]4, D\[\to \]2 done

clear

D)

A\[\to \]2, B\[\to \]4, C\[\to \]1, D\[\to \]5 done

clear

View Solution play_arrow

-

question_answer13)

Match List-I (Casting defects) with List-II (Explanation) and select the correct answer using the codes given below the lists:

| List-I (Casting defects) | List-II (Explanation) |

| A. | Metallic projections | 1. | Consist of rounded or rough projections internal or exposed cavities including blow holes and pin holes |

| B. | Cavities | 2. | Formed during melting, solidification and moulding |

| C. | Inclusions | 3. | Includes single folds, laps, scars adhering sand layers and oxide scale |

| D. | Discontinuities | 4. | Include cracks, cold or hot tearing and cold shuts |

| | 5. | Consist of fins, flash or massive projections ions and rough surface |

Codes:

A)

A\[\to \]1, B\[\to \]5, C\[\to \]3, D\[\to \]2 done

clear

B)

A\[\to \]1, B\[\to \]5, C\[\to \]2, D\[\to \]4 done

clear

C)

A\[\to \]5, B\[\to \]1, C\[\to \]2, D\[\to \]4 done

clear

D)

A\[\to \]5, B\[\to \]1, C\[\to \]3, D\[\to \]2 done

clear

View Solution play_arrow

-

question_answer14)

Which of the following are produced by slush

A)

Hollow castings with thick walls done

clear

B)

Hollow castings with thin walls done

clear

C)

Thin castings done

clear

D)

Thick castings done

clear

View Solution play_arrow

-

question_answer15)

Match List-I (Name of the process) with List-II (Advantage) and select the correct answer using the codes given below the lists:

| List-I (Name of the process) | List-II (Advantage) |

| A. | Sand casting | 1. | Large cylindrical parts with good quality |

| B. | Ceramic mold casting | 2. | excellent dimensional accuracy and surface finish |

| C. | Die casting | 3. | Intricate shapes and close tolerance parts |

| D. | Centrifugal casting | 4. | Almost any metal is cast and there is no limit to size, shape and weight |

| | 5. | Good dimensional accuracy, finish and low porosity |

Codes:

A)

A\[\to \]2, B\[\to \]3, C\[\to \]5, D\[\to \]1 done

clear

B)

A\[\to \]4, B\[\to \]1, C\[\to \]2, D\[\to \]3 done

clear

C)

A\[\to \]2, B\[\to \]1, C\[\to \]5, D\[\to \]3 done

clear

D)

A\[\to \]4, B\[\to \]3, C\[\to \]5, D\[\to \]1 done

clear

View Solution play_arrow

-

question_answer16)

Which one of the following processes consists of central spruces to feed metal into the cavities through a number of radial gates?

A)

Centrifuging done

clear

B)

Semi-centrifugal casting done

clear

C)

True centrifugal casting done

clear

D)

Precision casting done

clear

View Solution play_arrow

-

question_answer17)

The mould in shell moulding process is made up of which of the following?

A)

Gypsum + setting agents done

clear

B)

Green sand + clay done

clear

C)

Sodium silicate + dried sand done

clear

D)

dried silica + phenolic resin done

clear

View Solution play_arrow

-

question_answer18)

Which one of the following statements is not correct?

A)

In injection die moulding, exact amount of material to fill the cylinder is delivered done

clear

B)

Injection die moulding is generally limited to forming thermoplastic material done

clear

C)

Thermosetting plastics arc more suitable for extrusion moulding done

clear

D)

Extrusion moulding process is used for giving shapes, such as rods, tubes, pipes, ropes etc. done

clear

View Solution play_arrow

-

question_answer19)

Which one of the following is the process intermediate to compression and injection moulding?

A)

Reaction moulding done

clear

B)

transfer moulding done

clear

C)

Pelleting done

clear

D)

preheating done

clear

View Solution play_arrow

-

question_answer20)

Powder metallurgy process involves which of the following?

| 1. Converting metals such as iron etc. into powder form. |

| 2. Blending powders of. Metals, then compacting and compressing to desired shape at room temperature. |

| 3. Heating the compressed articles to a temperature above melting point of metal. |

Select the correct answer using the code given below:

A)

1, 2 and 3 done

clear

B)

1 and 2 only done

clear

C)

2 and 3 only done

clear

D)

1 and 3 only done

clear

View Solution play_arrow

-

question_answer21)

Which one of the following statements is correct? In green sand moulding process, uniform ramming leads to:

A)

Less sand expansion type of casting defect done

clear

B)

Greater dimensional stability of the casting done

clear

C)

Uniform flow of molten metal into the mould cavity done

clear

D)

Less chance of gas porosity done

clear

View Solution play_arrow

-

question_answer22)

The most preferred process for casting gas turbine blades is:

A)

Die moulding done

clear

B)

Shell moulding done

clear

C)

Investment moulding done

clear

D)

Sand casting done

clear

View Solution play_arrow

-

question_answer23)

Match List-I with List-II and select the correct answer using the codes given below the lists:

| List-I (Equipment) | List-II (Functions) |

| A. | Hot chamber | 1. | Cleaning machine |

| B. | Muller | 2. | Core making |

| C. | Dielectric baker | 3. | Die casting |

| D. | Sand blasting | 4. | Annealing |

| | 5. | Mixing |

Codes:

A)

A\[\to \]3, B\[\to \]5, C\[\to \]2, D\[\to \]1 done

clear

B)

A\[\to \]4, B\[\to \]2, C\[\to \]5, D\[\to \]3 done

clear

C)

A\[\to \]4, B\[\to \]2, C\[\to \]3, D\[\to \]1 done

clear

D)

A\[\to \]3, B\[\to \]5, C\[\to \]1, D\[\to \]2 done

clear

View Solution play_arrow

-

question_answer24)

Which of the following materials can be used for making patterns?

| 1. Aluminium |

| 2. Wax |

| 3. Mercury |

| 4. Lead |

Select the correct answer using the codes below:

A)

1, 3 and 4 done

clear

B)

2, 3 and 4 done

clear

C)

1, 2 and 4 done

clear

D)

1, 2 and 3 done

clear

View Solution play_arrow

-

question_answer25)

Directional solidification in castings can be improved by using:

A)

Chills and chaplets done

clear

B)

Chills and padding done

clear

C)

Chaplets and padding done

clear

D)

Chills, chaplets and padding. done

clear

View Solution play_arrow

-

question_answer26)

Consider the following ingredients used in moulding:

| 1. Dry silica sand |

| 2. Clay |

| 3. Phenol formaldehyde |

| 4. Sodium silicate |

Those used for shell mould casting include:

A)

1, 2 and 4 done

clear

B)

2, 3 and 4 done

clear

C)

1 and 3 done

clear

D)

1, 2, 3 and 4 done

clear

View Solution play_arrow

-

question_answer27)

Which of the following methods are used for obtaining directional solidification for riser design?

| 1. Suitable placement of chills. |

| 2. Suitable placement of chaplets. |

| 3. Employing padding. |

Select the correct answer:

A)

1 and 2 done

clear

B)

1 and 3 done

clear

C)

2 and 3 done

clear

D)

1, 2 and 3 done

clear

View Solution play_arrow

-

question_answer28)

Misrun is a casting defect which occurs due to:

A)

Very high pouring temperature of the metal done

clear

B)

Insufficient fluidity of the molten metal done

clear

C)

Absorption of gases by the liquid metal done

clear

D)

Improper alignment of the mould flasks done

clear

View Solution play_arrow

-

question_answer29)

Which of the following pairs are correctly matched?

| 1. Pit moulding for large jobs. |

| 2. Investment moulding lost wax process. |

| 3. Plaster moulding mould prepared in gypsum. |

A)

1, 2 and 3 done

clear

B)

1 and 2 done

clear

C)

1 and 3 done

clear

D)

2 and 3 done

clear

View Solution play_arrow

-

question_answer30)

Which one of the following pairs is not correctly matched?

A)

B)

C)

D)

View Solution play_arrow

-

question_answer31)

If the melting ratio of a cupola is 10:1, then the coke requirement for one ton melt will be:

A)

0.1 ton done

clear

B)

10 tons done

clear

C)

1 ton done

clear

D)

11 tons done

clear

View Solution play_arrow

-

question_answer32)

Which one of the following statements is not correct?

A)

The operating characteristic curve of an acceptance sampling plan shows the ability of the plan to distinguish between good and bad lots done

clear

B)

No sampling plan can give complete protection against the acceptance of defective products done

clear

C)

C chart has straight line limits and U chart has zig-zag limits done

clear

D)

Double sampling result in more inspection than single sampling if the incoming quality is very bad done

clear

View Solution play_arrow

-

question_answer33)

Which of the following are the requirements of an ideal gating system?

| 1. The molten metal should enter the mould cavity with as high a velocity as possible. |

| 2. It should facilitate, complete fillings of the mould cavity. |

| 3. It should be able to prevent the absorption of air or gases from the surroundings on the molten metal while flowing through it. |

Select the correct answer using the codes given below:

A)

1, 2 and 3 done

clear

B)

1 and 2 done

clear

C)

2 and 3 done

clear

D)

1 and 3 done

clear

View Solution play_arrow

-

question_answer34)

A spherical drop of molten metal of radius 2 mm was found to solidify in 10 seconds. A similar drop of radius 4 mm would solidify in:

A)

14.14 second done

clear

B)

20 seconds done

clear

C)

18.30 second done

clear

D)

40 seconds done

clear

View Solution play_arrow

-

question_answer35)

In solidification of metal during casting, compensation for solid contraction is:

A)

Provided by the oversize pattern done

clear

B)

Achieved by properly placed risers done

clear

C)

Obtained by promoting direction solidification done

clear

D)

Made by providing chills done

clear

View Solution play_arrow

-

question_answer36)

Match List-I (Types of casting) with List-II (Working principles) and select the correct answer using the codes given below the lists:

| List-I | List-II |

| A. | Die casting | 1. | Molten metal is forced into the die under pressure |

| B. | Centrifugal casting | 2. | Axis of rotation does not coincide with axis of mould |

| C. | Centrifuging casting | 3. | Metal solidifies when mould is rotating |

| D. | Continuous casting | 4. | Continuously pouring molten metal into mould |

Codes:

A)

A\[\to \]1, B\[\to \]3, C\[\to \]2, D\[\to \]4 done

clear

B)

A\[\to \]4, B\[\to \]3, C\[\to \]2, D\[\to \]1 done

clear

C)

A\[\to \]1, B\[\to \]2, C\[\to \]3, D\[\to \]4 done

clear

D)

A\[\to \]4, B\[\to \]2, C\[\to \]3, D\[\to \]1 done

clear

View Solution play_arrow

-

question_answer37)

Match List-I (Process)with List-II (Products/ materials) and select the correct answer using the codes given below the lists:

| List-I | List-II |

| A. | Die casting | 1. | Phenol formaldehyde |

| B. | Shell moulding | 2. | CI. Pipes |

| C. | \[C{{O}_{2}}\]moulding | 3. | Non-ferrous alloys |

| D. | Centrifugal casting | 4. | Sodium silicate |

Codes:

A)

A\[\to \]1, B\[\to \]3, C\[\to \]4, D\[\to \]2 done

clear

B)

A\[\to \]3, B\[\to \]1, C\[\to \]4, D\[\to \]2 done

clear

C)

A\[\to \]3, B\[\to \]1, C\[\to \]2, D\[\to \]4 done

clear

D)

A\[\to \]1, B\[\to \]3, C\[\to \]2, D\[\to \]4 done

clear

View Solution play_arrow

-

question_answer38)

The main purpose of chaplets is:

A)

To ensure directional solidification done

clear

B)

To provide efficient venting done

clear

C)

For aligning the mould boxes done

clear

D)

To support the cores done

clear

View Solution play_arrow

-

question_answer39)

Scab is a:

A)

Sand casting defect done

clear

B)

machining defect done

clear

C)

Welding defect done

clear

D)

forging defect done

clear

View Solution play_arrow

-

question_answer40)

The gating ratio 2 : 8 : 1 for copper in gating system design refers to the ratio of areas of:

A)

Sprue : runner : ingate done

clear

B)

Runner: ingate : sprue done

clear

C)

Runner : sprue : ingate done

clear

D)

Ingate : runner : sprue done

clear

View Solution play_arrow

-

question_answer41)

Which one of the following processes produces casting when pressure forces the molten metal into the mould cavity?

A)

Shell moulding done

clear

B)

investment casting done

clear

C)

Die casting done

clear

D)

continuous casting done

clear

View Solution play_arrow

-

question_answer42)

In shell moulding, how can the shell thickness h accurately maintained?

A)

By controlling the time during which the pattern is in contact with mould done

clear

B)

By controlling the time during which the pattern is heated. done

clear

C)

By maintaining the temperature of the pattern in the range of \[175{}^\circ C-380{}^\circ C\] done

clear

D)

By the type of binder used done

clear

View Solution play_arrow

-

question_answer43)

In gating system design, which one of the following is the correct sequence in which choke area, pouring time, pouring basin and sprue sizes are calculated?

A)

Choke area - pouring time - pouring basin -sprue done

clear

B)

Pouring basin - sprue - choke area - pouring done

clear

C)

Choke area - sprue - pouring basin ? pouring time done

clear

D)

Pouring basin - pouring time - choke area - sprue done

clear

View Solution play_arrow

-

question_answer44)

In which of the following are metal moulds used?

A)

Greensand mould done

clear

B)

dry sand mould done

clear

C)

Die casting process done

clear

D)

loan moulding done

clear

View Solution play_arrow

-

question_answer45)

Which of the following materials are used for making patterns in investment casting method?

| 1. Wax |

| 2. Rubber |

| 3. Wood |

| 4. Plastic |

| Select the correct answer using the code given below: |

Code:

A)

Only 1 and 3 done

clear

B)

Only 2 and 3 done

clear

C)

Only 1, 2 and 4 done

clear

D)

Only 2, 3 and 4 done

clear

View Solution play_arrow

-

question_answer46)

Shell moulding can be used for:

A)

Producing milling cutters done

clear

B)

Making gold ornaments done

clear

C)

Producing heavy and thick walled casting done

clear

D)

Producing thin casting done

clear

View Solution play_arrow

-

question_answer47)

According to Chvorinov's equation, the solidification time of a casting is proportional to: Where, v = volume of casting

A)

\[{{v}^{2}}\] done

clear

B)

\[v\] done

clear

C)

\[1/v\] done

clear

D)

\[1/{{v}^{2}}\] done

clear

View Solution play_arrow

-

question_answer48)

A gating ratio of 1 : 2 : 4 is used to design the gating system for magnesium alloy casting. This gating ratio refers to the cross-section areas of the various gating elements as given below:

| 1. Down sprue |

| 2. Runner bar |

| 3. Ingates |

The correct sequence of the above elements in the ratio 1 : 2 : 4 is:

A)

1, 2 and 3 done

clear

B)

1, 3 and 2 done

clear

C)

2, 3 and 1 done

clear

D)

3, 1 and 2 done

clear

View Solution play_arrow

-

question_answer49)

Match List I (Products) with List II (Casting process) and select the correct answer using "the codes given below the lists :

| List-I (Products) | List-II (Casting process) |

| A. | Hollow statues | 1. | Centrifugal casting |

| B. | Dentures | 2. | Investment casting |

| C. | Aluminium alloy pistons | 3. | Slush casting |

| D. | Rocker arms | 4. | Shell moulding |

| | 5. | Gravity die casting |

Codes:

A)

A\[\to \]3, B\[\to \]1, C\[\to \]4, D\[\to \]5 done

clear

B)

A\[\to \]1, B\[\to \]3, C\[\to \]4, D\[\to \]5 done

clear

C)

A\[\to \]1, B\[\to \]2, C\[\to \]3, D\[\to \]4 done

clear

D)

A\[\to \]3, B\[\to \]2, C\[\to \]5, D\[\to \]4 done

clear

View Solution play_arrow

-

question_answer50)

Match List-I (Type of moulding) with List-II (Mechanism involved) and select the correct answer using the codes given below the lists:

| List-I (Type of moulding) | List-II (Type of moulding) |

| A. | Compression moulding | 1. | Mould cavity-must be heated to cure the plastic forced into it |

| B. | Injected | 2. | Similar to Hydraulic extrusion |

| C. | Jet moulding | 3. | analogous to hot-pressing of powdered metals |

| D. | Extrusion moulding | 4. | analogous to die casting of metals |

Codes:

A)

A\[\to \]2, B\[\to \]4, C\[\to \]3, D\[\to \]1 done

clear

B)

A\[\to \]3, B\[\to \]1, C\[\to \]4, D\[\to \]2 done

clear

C)

A\[\to \]2, B\[\to \]1, C\[\to \]3, D\[\to \]4 done

clear

D)

A\[\to \]3, B\[\to \]4, C\[\to \]2, D\[\to \]1 done

clear

View Solution play_arrow

-

question_answer51)

Match List-I with List-II and select the correct answer using the codes 'given below the lists:

| List-I (Casting process) | List-II (Principle) |

| A. | Die casting | 1. | The metal solidifies in a rotating mould |

| B. | Investment casting | 2. | The pattern cluster is repeatedly dipped into a ceramic slurry and dusted with refractory |

| C. | Shell moulding | 3. | Molten metal is forced by pressure into a metallic mould |

| D. | Centrifugal casting | 4. | After cooling, the invest is removed from the casting by pressure jetting or vibratory cleaning |

Codes:

A)

A\[\to \]2, B\[\to \]1, C\[\to \]3, D\[\to \]4 done

clear

B)

A\[\to \]3, B\[\to \]4, C\[\to \]2, D\[\to \]1 done

clear

C)

A\[\to \]2, B\[\to \]4, C\[\to \]3, D\[\to \]1 done

clear

D)

A\[\to \]3, B\[\to \]1, C\[\to \]2, D\[\to \]4 done

clear

View Solution play_arrow

-

question_answer52)

Consider the following statements1 in respect of investment castings:

| 1. The pattern or patterns is/are not jointed to a stalk or spure also of wax to form a tree of patterns. |

| 2. The prepared moulds are placed in an oven and, heated gently to dry off the invest and melt out the bulk of wax. |

| 3. The moulds are usually poured by placing the moulds in a vacuum chamber. |

Which of the statements given above are correct?

A)

1 and 2 only done

clear

B)

1 and 3 only done

clear

C)

2 and 3 only done

clear

D)

1, 2 and 3 done

clear

View Solution play_arrow

-

question_answer53)

Which of the following are employed in shell moulding?

| 1. Resin binder |

| 2. Metal pattern |

| 3; Heating coils |

Select the correct answer using the code given below:

A)

1 and 2 only done

clear

B)

1 and 3 only done

clear

C)

2 and 3 only done

clear

D)

1, 2 and 3 done

clear

View Solution play_arrow

-

question_answer54)

Which one of the following is the correct statement? In a centrifugal casting method:

A)

No core is used done

clear

B)

Core may be made of any metal done

clear

C)

Core is made of sand done

clear

D)

Core is made of ferrous metal done

clear

View Solution play_arrow

-

question_answer55)

Which cute of the following is the correct statement? Gate is provided in moulds to:

A)

Feed the casting at a constant rate done

clear

B)

Give passage to gases done

clear

C)

Compensate for shrinkage done

clear

D)

Avoid cavities done

clear

View Solution play_arrow

-

question_answer56)

Bottom gating system is sometimes preferred in casting because:

A)

It enables rapid filling of mould cavity done

clear

B)

It is easier to provide in the mould done

clear

C)

It provides cleaner metal done

clear

D)

It reduces splashing and turbulence done

clear

View Solution play_arrow

-

question_answer57)

The pattern adopted for those castings where there are some portions which are structurally weak and are likely to break by the force of ramming are called:

A)

Loose piece pattern done

clear

B)

follow board pattern done

clear

C)

Skelton pattern done

clear

D)

single piece pattern done

clear

View Solution play_arrow

-

question_answer58)

Which of the following casting processes does not do not require Central core for producing pipe?

| 1. Sand casting process |

| 2. Die casting process |

| 3. Centrifugal casting process |

Select the correct answer using the code given below:

A)

1 and 2 done

clear

B)

2 only done

clear

C)

2 and 3 done

clear

D)

3 only done

clear

View Solution play_arrow

-

question_answer59)

Small amount of carbonaceous material sprinkled on the inner surface of mould cavity is called:

A)

Backing sand done

clear

B)

facing sand done

clear

C)

Green sand done

clear

D)

dry sand done

clear

View Solution play_arrow

-

question_answer60)

A standard \[90{}^\circ V\]-notch weir is used to measure discharge. The discharge is \[{{Q}_{1}}\] for a height \[{{H}_{1}}\] above the sill and \[{{Q}_{2}}\] is the discharge for a height \[{{H}_{2}}.\]If \[{{\text{H}}_{\text{2}}}\text{/}{{\text{H}}_{\text{1}}}\] is 4, then \[{{Q}_{\text{2}}}\text{/}{{\text{Q}}_{\text{1}}}\] is:

A)

32 done

clear

B)

\[16\sqrt{2}\] done

clear

C)

16 done

clear

D)

8 done

clear

View Solution play_arrow

-

question_answer61)

A right circular cylinder is filled with a liquid upto its top level. It is rotated about its vertical axis at such a speed that half the liquid spills out, then the pressure at the point of intersection of the axis and bottom surface is:

A)

Same as before rotation done

clear

B)

Half on the value before rotation done

clear

C)

Quarter of the value before rotation done

clear

D)

Equal to atmospheric pressure done

clear

View Solution play_arrow

-

question_answer62)

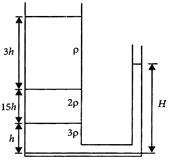

Three immiscible liquids of specific densities \[\rho ,\,2\rho \] and \[3\rho \] are kept in a jar. The height of the liquids a jar and at the piezometer fitted to the bottom of the air are as shown in the given figure. The ratio H/h is:

A)

4 done

clear

B)

3.5 done

clear

C)

3 done

clear

D)

2.5 done

clear

View Solution play_arrow

-

question_answer63)

Which one of the following sequences indicates the correct order for flue gas flow in the steam power plant layout?

A)

Superheater, economiser, air preheater done

clear

B)

Economiser, air preheater, superheater done

clear

C)

Air preheater, economiser, superheater done

clear

D)

Economiser, superheater, air preheater. done

clear

View Solution play_arrow

-

question_answer64)

Which one of the following statements is not corral In a fluidized-bed boiler:

A)

The combustion temperatures are higher than those in the conventional boilers done

clear

B)

Inferior grade of coal can be used without slagging problems done

clear

C)

The formation of NO, is less than that in conventional boilers done

clear

D)

The volumetric heat release rates are higher than those in the conventional boilers done

clear

View Solution play_arrow

-

question_answer65)

Consider the following statements:

| Sub cooling in the condenser of a refrigeration system is advisable when: |

| 1. Expansion valve is at a higher elevation condenser. |

| 2. There is a large pressure drop in the line connecting condenser to the expansion valve. |

| 3. The refrigeration effect is to he increased. |

| 4. The compressor work is to he reduced |

Which of these statements are correct?

A)

1 and 2 done

clear

B)

1, 3 and 4 done

clear

C)

2, 3 and 4 done

clear

D)

1, 2 and 3 done

clear

View Solution play_arrow

-

question_answer66)

Match List-I (Machines) with List-II (Features) and select the correct answer using the codes given below the lists:

| List-I (Machine) | List-II (Features) |

| A. | Steam engine | 1. | Velocity compounding |

| B. | Impulse turbine | 2. | Diagram factor |

| C. | Reaction turbine | 3. | Continuous pressure drop |

| D. | Centrifugal compressore | 4. | Isentropic efficiency |

Codes:

A)

A\[\to \]3, B\[\to \]4, C\[\to \]2, D\[\to \]1 done

clear

B)

A\[\to \]2, B\[\to \]1, C\[\to \]3, D\[\to \]4 done

clear

C)

A\[\to \]2, B\[\to \]4, C\[\to \]3, D\[\to \]1 done

clear

D)

A\[\to \]3, B\[\to \]1, C\[\to \]2, D\[\to \]4 done

clear

View Solution play_arrow

-

question_answer67)

For maximum blade efficiency of a single-stage impulse turbine, the blade speed ratio, (\[\alpha \] is the angle made by absolute velocity at inlet) should be:

A)

\[\cos \,2\alpha \] done

clear

B)

\[\frac{\cos \,2\alpha }{2}\] done

clear

C)

\[\frac{\cos \alpha }{2}\] done

clear

D)

\[\frac{2}{\cos \alpha }\] done

clear

View Solution play_arrow

-

question_answer68)

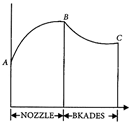

The given figure shows the variation of certain steam parameter in case of a simple impulse turbine. The curve A-B-C represents the variation of:

A)

Pressure in nozzle and blades done

clear

B)

Velocity in nozzle and blades done

clear

C)

Temperature in nozzle and blades done

clear

D)

Enthalpy in nozzle and blades done

clear

View Solution play_arrow

-

question_answer69)

A solar-absorption refrigeration system has generator temperature of \[87{}^\circ C\] evaporator temperature of \[-3{}^\circ C\] condenser and absorber temperatures of \[27{}^\circ C\] each, then its maximum possible COP is:

A)

10.0 done

clear

B)

9.0 done

clear

C)

1.80 done

clear

D)

1.50 done

clear

View Solution play_arrow

-

question_answer70)

The flow in the vaneless space between the impeller exit and diffuser inlet of a centrifugal compressor can be assumed as:

A)

Free vortex done

clear

B)

forced vortex done

clear

C)

Solid body rotation done

clear

D)

logarithimic spiral done

clear

View Solution play_arrow

-

question_answer71)

Which of the following statement (s) is/are relevant to critical flow through a steam nozzle?

| 1. Flow rate through the nozzle is minimum. |

| 2. Flow rate through the nozzle is maximum. |

| 3. Velocity at the throat is supersonic. |

| 4. Velocity at the throat is sonic. |

| Select the correct answer using the codes given below: |

Codes:

A)

1 alone done

clear

B)

1 and 3 done

clear

C)

2 and 4 done

clear

D)

4 alone done

clear

View Solution play_arrow

-

question_answer72)

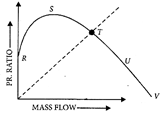

Which portion of the centrifugal compressor characteristics shown in the figure is difficult to obtain experimentally?

A)

RS done

clear

B)

ST done

clear

C)

TU done

clear

D)

UV done

clear

View Solution play_arrow

-

question_answer73)

Consider the following statements regarding the axial flow in an air compressor:

| 1. Surging is a local phenomenon while stalling affects the entire compressor. |

| 2. Stalling is a local phenomenon while surging affects the entire compressor. |

| 3. The pressure ratio of an axial compressor stage is smaller than that of a centrifugal compressor stage. |

Of these statements:

A)

1, 2 and 3 are correct done

clear

B)

1 and 2 are correct done

clear

C)

2 and 3 correct done

clear

D)

1 and 3 correct done

clear

View Solution play_arrow

-

question_answer74)

Match List-I (Expansion device) with List-II (Operation) and select the correct answer using the codes given below the lists:

| List-I (Expansion device) | List-II (Operation) |

| A. | Float valve | 1. | Constant degree of superheat at evaporator exit pressure |

| B. | Automatic expansion valve | 2. | Constant degree of superheat at evaporator inlet pressure |

| C. | Internally equalized thermostatic expansion valve | 3. | Constant level of refrigerant in the evaporator |

| D. | Extrammaly equalized thermostatic expansion valve | 4. | Constant pressure in the evaporator |

Codes:

A)

A\[\to \]1, B\[\to \]2, C\[\to \]4, D\[\to \]3 done

clear

B)

A\[\to \]3, B\[\to \]2, C\[\to \]4, D\[\to \]1 done

clear

C)

A\[\to \]3, B\[\to \]4, C\[\to \]2, D\[\to \]1 done

clear

D)

A\[\to \]1, B\[\to \]4, C\[\to \]2, D\[\to \]3 done

clear

View Solution play_arrow

-

question_answer75)

Consider the specific speed ranges of the following types of turbines:

| 1. Francis |

| 2. Kaplan |

| 3. Pelton. |

The sequence of their specific speed in increasing order is:

A)

1, 2, 3 done

clear

B)

3, 1, 2 done

clear

C)

3, 2, 1 done

clear

D)

2, 3, 1 done

clear

View Solution play_arrow

-

question_answer76)

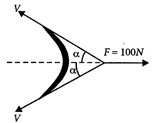

A symmetrical stationary vane experiences a force 'F' of 100 N as shown in the given figure, when the mass of flow rate of water over the vane is 5 kg/s with a velocity ?V? of 20 m/s without friction. The angle \['\alpha '\] of the vane is:

A)

Zero done

clear

B)

\[30{}^\circ \] done

clear

C)

\[45{}^\circ \] done

clear

D)

\[60{}^\circ \] done

clear

View Solution play_arrow

-

question_answer77)

In a fluid coupling, the torque transmitted is 50 kN.m, when the speed of the driving and driven shaft is 900 rpm and 720 rpm respectively. The efficiency of the fluid coupling will be:

A)

20% done

clear

B)

25% done

clear

C)

80% done

clear

D)

90%. done

clear

View Solution play_arrow

-

question_answer78)

Consider the following statements regarding the fluid coupling:

| 1. Efficiency increases with increase in speed ratio. |

| 2. Neglecting friction the output torque is equal to input torque. |

| 3. At the same input speed, higher slip requires higher input torque. |

Which of these statements are correct?

A)

1, 2 and 3 done

clear

B)

1 and 2 done

clear

C)

2 and 3 done

clear

D)

1 and 3 done

clear

View Solution play_arrow

-

question_answer79)

The level of runner exit is 5 m above the tail race, and atmospheric pressure is 10.3 m. The pressure at the exit of the runner for a divergent draft tube can be:

A)

5 m done

clear

B)

5.3 m done

clear

C)

10 m done

clear

D)

10.3 m done

clear

View Solution play_arrow

-

question_answer80)

Consider the following statements:

| A surge tank provided on the penstock connected to a water turbine |

| 1. Helps in reducing the water hammer |

| 2. Stores extra water when not needed. |

| 3. Provides increased demand of water. |

Which of these statements are correct?

A)

1 and 3 done

clear

B)

2 and 3 done

clear

C)

1 and 2 done

clear

D)

1, 2 and 3 done

clear

View Solution play_arrow

-

question_answer81)

If a reciprocating pump having a mechanical efficiency of 80% delivers water at the rate of 80 kg/s with a head of 30 m, the brake power of the pump is:

A)

29.4 kW done

clear

B)

20.8 kW done

clear

C)

15.4 kW done

clear

D)

10.8 kW done

clear

View Solution play_arrow

-

question_answer82)

The vertical component of force on a curved surface submerged in a static liquid is equal to the

A)

Weight of liquid column above the C.G. of the curved surface done

clear

B)

Weight of liquid above the curved surface done

clear

C)

Product of pressure at C.G, multiplied by the area of the curved surface done

clear

D)

Product of pressure at C.G, multiplied by the projected area of the curved surface. done

clear

View Solution play_arrow

-

question_answer83)

Consider the following statements pertaining to a centrifugal pump

| 1. The manometric head is the head developed by |

| 2. The suction pipe has, generally, a larger diameter as compared to the discharge pipe. |

| 3. The suction pipe is provided with a foot valve and a strainer. |

| 4. The delivery pipe is provided with a foot valve and a strainer. |

Of these statements:

A)

1, 2 and 3 and 4 are correct done

clear

B)

1 and 2 are correct done

clear

C)

2 and 3 are correct done

clear

D)

1 and 3 are correct done

clear

View Solution play_arrow

-

question_answer84)

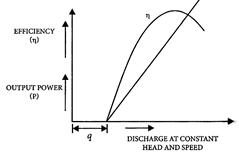

For a water turbine, running at constant head and speed, the operating characteristics curves in the given figure show, that upto a certain discharge 'q' both output power and efficiency remain zero. The discharge 'q' is required to:

A)

Overcome initial inertia done

clear

B)

Overcome initial friction done

clear

C)

Keep the hydraulic circuit full done

clear

D)

Keep the turbine running at no load done

clear

View Solution play_arrow

-

question_answer85)

In fluid machinery, the relationship between saturation temperature and pressure decides the process of:

A)

Flow separation done

clear

B)

turbulent mixing done

clear

C)

Cavitation done

clear

D)

water hammer done

clear

View Solution play_arrow

-

question_answer86)

A centrifugal blower delivering \[\text{Q}{{\text{m}}^{\text{3}}}\text{/s}\] against a head of H m is driven at half the original speed. The new head and discharge would be:

A)

\[H\,and\,Q/2\] done

clear

B)

\[\frac{H}{4}\,and\,\frac{Q}{2}\] done

clear

C)

\[\frac{H}{2}\,and\,\frac{Q}{8}\] done

clear

D)

\[H\,and\,\frac{Q}{4}\] done

clear

View Solution play_arrow

-

question_answer87)

The maximum number of jets generally employed in an impulse turbine without jet interference is:

A)

4 done

clear

B)

6 done

clear

C)

8 done

clear

D)

12 done

clear

View Solution play_arrow

-

question_answer88)

A hydraulic coupling transmits 1 kW of power at an input speed of 200 rpm, with a slip of 2%. If the input speed is changed to 400 rpm, the power transmitted with the same slip is:

A)

2 kW done

clear

B)

1/2 kW done

clear

C)

4 kW done

clear

D)

8 Kw done

clear

View Solution play_arrow