Controlling

Category :

8. Controlling

INTRODUCTION

This chapter explains the meaning of controlling - its concept and importance and highlights the relationship between planning and controlling, and explains the steps in the process of controlling.

Chapter at a Glance

MEANING OF CONTROLLING

Controlling refers to comparison of actual performance with the planned performance and taking correction actions, in case of deviations between actual and planned performance.

In words of, Koontz and O' Donnel,

Managerial Control implies the measurement of accomplishment against the standard and the correction of deviations to assure attainment of objectives according to plans

NATURE OF CONTROLLING

(i) Goal oriented: Controlling is a goal - oriented function as it aims to ensure that resources are used effectively and efficiently to achieve predetermined goals.

(ii) Pervasive: Controlling is a pervasive function as control is exercised at all levels of management. The nature and extent of control may differ from level to level. Moreover, controlling is required in both business and non - business organisations.

(iii) Controlling is both a backward looking as well as forward looking function:

It is backward - looking function as it measures and compares actual performance with standards fixed in the past.

It is also a forward - looking function as it aims to improve future performance, based on experience gained in the past.

(iv) Controlling is a continuous function as it involves continuous review of performance and revision of standards.

Important Note:

Controlling should not be misunderstood as the last function of management. It is a function that brings back the management cycle back to the planning function.

· Controlling function determines how far actual performance deviates from standards, analysis the causes of such deviations and attempts to take corrective actions based on the same.

· This process helps to formulate future plans in the light of problems identified and helps in better planning in the future periods.

Thus, controlling only completes one cycle of management process and improves planning in the next cycle.

IMPORTANCE OF CONTROLLING

(i) Accomplishing organisational goals:

(a) The controlling function measures the progress towards the organisational goals and brings to light the deviations, if any and indicates corrective action.

(b) It thus, guides the organisation and keeps it on the right track so that organizational goals might be achieved.

(ii) Judging accuracy of standards:

(a) A good control system enables management to verify whether the standards set are accurate and objective.

(b) An efficient control system keeps a careful check on the changes taking place in the organisation and in the environment and helps to review and revise the standards in light of such changes.

(iii) Making efficient use of resources:

(a) By exercising control, a manager seeks to reduce wastage and spoilage of resources. Each activity is performed in accordance with predetermined standards and norms.

(b) Controlling ensures that resources are used in the most effective and efficient manner.

(iv) Improving employee motivation:

(a) A good control system ensures that employee know well in advance what they are expected to do and what are the standards of performance on the basis of which they will be appraised.

(b) It thus motivates them and helps them to give better performance.

(v) Ensuring order and discipline:

(a) Controlling creates an atmosphere of order and discipline in the organisation.

(b) It helps to minimise dishonest behaviour on the part of the employees by keeping a close check on their activities.

(vi) Facilitating coordination in action:

(a) Controlling provides direction to all activities and efforts for achieving organizational goals.

(b) Each department and employee is governed by pre- determined standards which are well coordinated with one another. This ensures that overall organisational objectives are accomplished.

RELATIONSHIP BETWEEN PLANNING AND CONTROLLING

The basis of the relationship between planning and controlling are:

(i) Planning and controlling are interdependent and interrelated activities:

(a) They are interdependent in the sense that:

· Planning provides basis (i.e., standards) for the controlling activities. In the absence of planning, the controlling activities cannot be performed because no fixed standards are available with which actual performance may be compared.

· Planning provides basis for improvement in future plans

· Planning is basically an intellectual process involving thinking, articulation and analysis to discover and prescribe an appropriate course of action for achieving objectives.

Controlling, on the other hand, checks whether decisions have been translated into desired action. Planning is thus, prescriptive whereas, controlling is evaluative.

· In the absence of effective controlling, planned activities cannot be properly implemented in accordance with the plans and programmes of the organisation and there cannot be improvement in future plans

· Controlling ensures realising planned goals efficiently through its feedback mechanism.

(b) Planning and controlling are interrelated and, in fact, they reinforce each other in the sense that

· Planning based on facts makes controlling easier and effective; and

· Controlling improves future planning by providing information derived from past experience.

· Planning without controlling is meaningless and controlling without planning is blind.

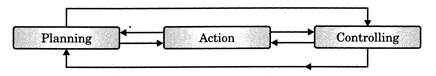

Note: Their mutual relationship can be judged from the figure:

Controlling has to be linked with planning and control mechanisms should be inbuilt into the plan itself. The more precise and accurate this linkage, the more effective the controlling system.

(ii) Planning and controlling both are Forward Looking and Backward Looking:

(a) Planning is forward looking in the sense that it looks at future and lays down the standards to be achieved in future.

(b) Controlling is looking back in the sense that it looks at past and measures the actual performance relating to the past and compares actual performance with planned performance and taking corrective measures in case of deviation.

(c) Planning is backward looking also in the sense as it is guided by past experiences and the corrective action initiated by control function aims to improve future performance.

(d) Controlling is not only looking back but also forward looking like planning in the sense that it helps in the adoption of new plans (if existing plan cannot be implemented at all) and revision of the existing plans (if existing plan can be implemented only with modifications) on the basis of comparison of actual performance with the prescribed standards.

(e) Controlling provides valuable information derived from past experience for future planning. It ensures better utilisation of resources in future by rectifying past mistakes.

Thus, planning and controlling are both backward-looking as well as a forward looking function.

CONTROLLING PROCESS

Following steps are involved in controlling process.

Step 1: Setting Performance Standards:

(i) The first step in the controlling process is setting up of performance standards.

(ii) Standards are the criteria against which actual performance would be measured. Thus, standards serve as benchmarks towards which an organisation strives to work.

(iii) Standards can be set in both quantitative as well as qualitative terms.

(iv) For instance,

(a) Standards set in terms of cost to be incurred, revenue to be earned, product units to be produced and sold, time to be spent in performing a task, all represents quantitative standards.

(b) Sometimes standards may also be set in qualitative terms. Improving goodwill and motivation level of employees are examples of qualitative standards.

Step 2: Measurement of Actual Performance:

(i) Once performance standards are set, the next step is measurement of actual performance.

(ii) Performance should be measured in an objective and reliable manner.

(iii) There are several techniques for measurement of performance. These include personal observation, sample checking, performance reports, etc.

(iv) As far as possible, performance should be measured in the same units in which standards are set as this would make their comparison easier.

Step 3: Comparing Actual Performance with Standards:

(i) This step involves comparison of actual performance with the standard. Such comparison will reveal the deviation between actual and desired results.

(ii) Comparison becomes easier when standards are set in quantitative terms.

(iii) For instance, performance of a worker in terms of units, produced in a week can be easily measured against the standard output for the week.

Step 4: Analysing Deviations:

(i) Some deviation in performance can be expected in all activities. It is, therefore, important to determine the acceptable range of deviations.

(ii) Also, deviations in key areas of business need to be attended more urgently as compared to deviations in certain insignificant areas. Critical point control and management by exception should be used by a manager in this regard.

(a) Critical Point Control:

· It is neither economical nor easy to keep a check on each and every activity in an organisation.

· Control should, therefore, focus on key result areas (KRAs) which are critical to the success of an organisation. These KRAs are set as the critical points. If anything goes wrong at the critical points, the entire organisation suffers.

· For instance, in a manufacturing organisation, an increase of 5 per cent in the labour cost may be more troublesome than a 15 per cent increase in postal charges.

(b) Management by Exception:

· Management by exception, which is often referred to as control by exception, is an important principle of management control based on the belief that an attempt to control everything results in controlling nothing.

· Thus, only significant deviations which go beyond the permissible limit should be brought to the notice of management.

· Thus, if the plans lay down 2 per cent increase in labour cost as an acceptable range of deviation in a manufacturing organisation, only increase in labour cost beyond 2 per cent should be brought to the notice of the management. However, in case of major deviation from the standard (say, 5 per cent), the matter has to receive immediate action of management on a priority basis.

Step 5: Taking Corrective Action:

(i) The final step in the controlling process is taking corrective action. No corrective action is required when the deviations are within acceptable limits.

(ii) However, when the deviations go beyond the acceptable range, especially in the important areas, it demands immediate managerial attention so that deviations do not occur again and standards are accomplished.

(iii) Corrective action might involve training of employees if the production target could not be met.

(iv) Similarly, if an important project is running behind schedule, corrective action might involve assigning of additional workers and equipment to the project and permission for overtime work.

Words that Matter

1. Controlling: Managericil control implies the measurement of accomplishment against the standard and the correction of deviations to assure attainment of objectives according to plans

2. Standards: Standards are the criteria against which actual performance is measured. Thus, standards serve as benchmarks towards which an organisation strives to work.

3. Quantitative Standards: Standards set in terms of cost to be incurred, revenue to be earned, product units to be produced and sold, time to be spent in performing a task.

4. Qualitative Standards: Sometimes standards may also be set in qualitative terms. Improving goodwill and motivation level of employees are examples of qualitative standards.

5. Management by exception: It is often referred to as control by exception. It is an important principle of management control based on the belief that an attempt to control everything results in controlling nothing.

You need to login to perform this action.

You will be redirected in

3 sec